What is a circular product?

Currently, there is no industry standard for recyclable products. We can use no agreed definition or criteria as a basis. What is clear, however, is that we need to manufacture products that

- can be used for longer

- are created to be created from scratch

- are made from safe and recycled raw materials

Think circular,

carry responsibility

Design criteria for circular economy

We consider the impact of production with every new product and the entire life cycle. We thoroughly research materials, processes and emerging technologies to understand and reduce the environmental footprint of each product.

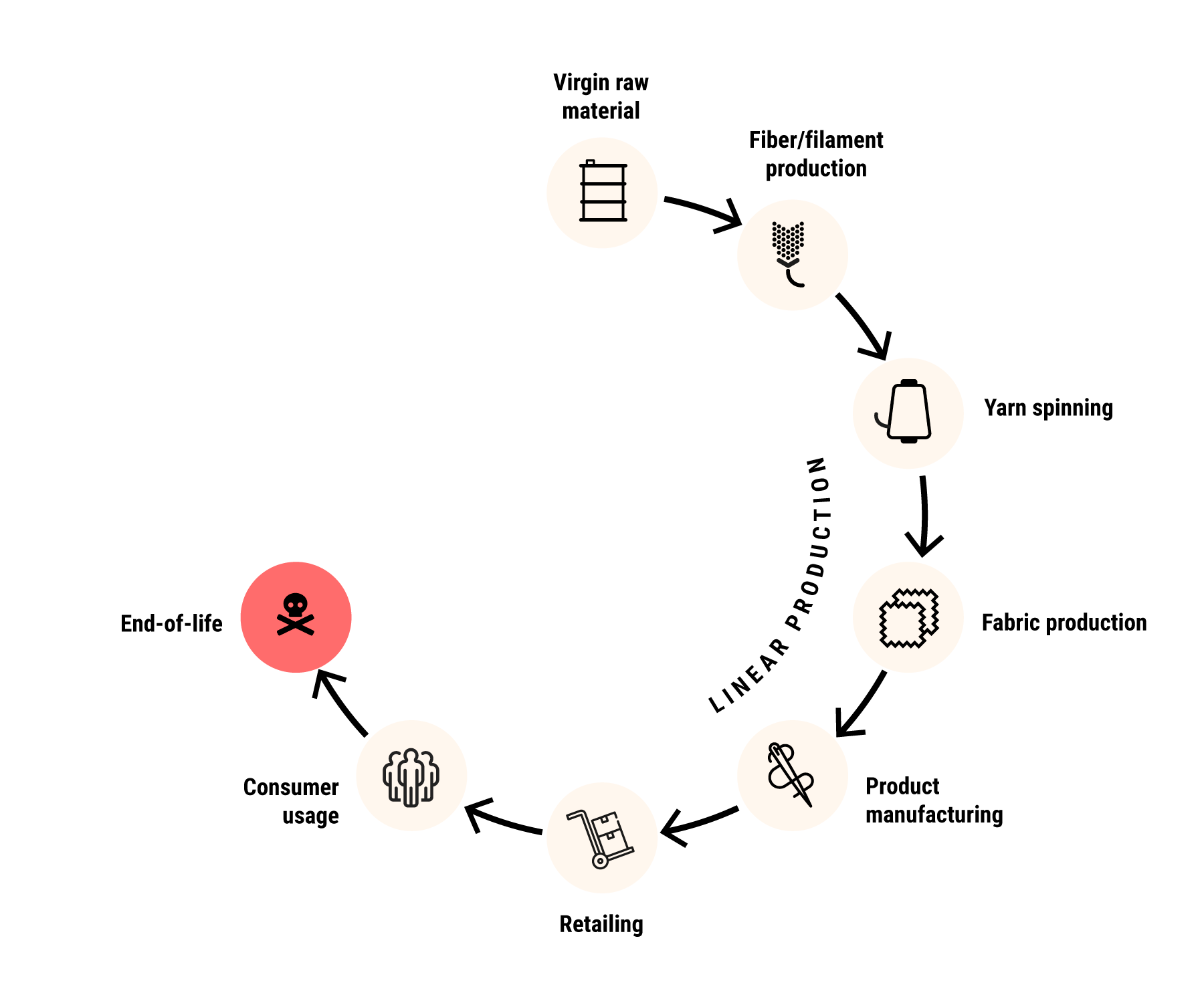

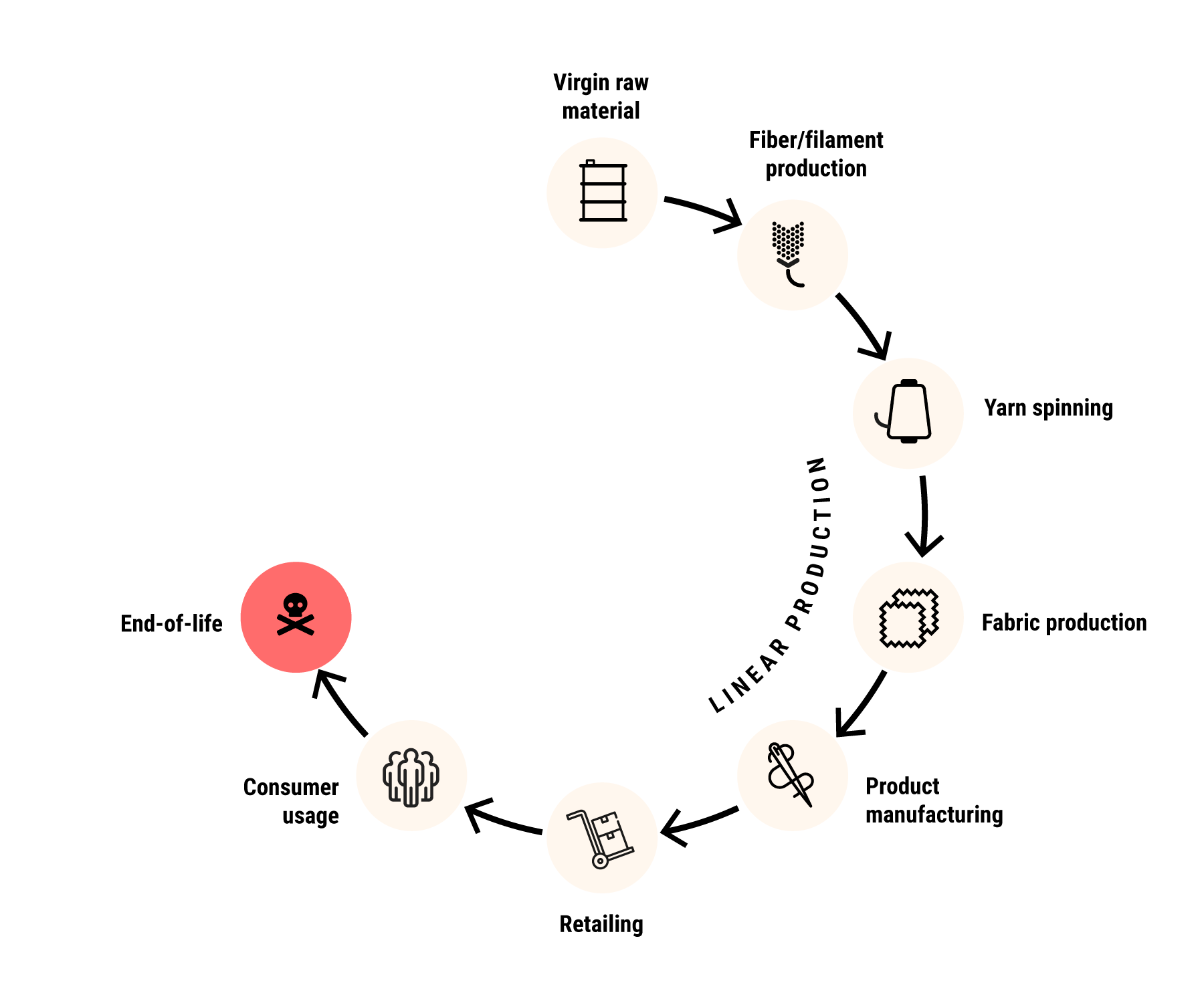

However, designing circular products requires not just an extra step in the process, but an entirely new approach. Every design decision affects the circularity of a product. In the shift from a linear to a circular economy, all components - from materials to fabric treatment - must undergo a review based on the following criteria:

1

Reduced environmental impact

Challenges in circular design

Durability and recyclability are not always compatible, which often leads to trade-offs between making products that last and those that are easy to recycle at the end of their life. Durable products often require additional reinforcements that are more complicated to disassemble and recycle later. Recyclable products require mono-fibers that do not always offer the same performance, functionality or durability.

Our design developments focus on durability, as bags and backpacks are meant to be used daily and intensively for years. Minimalist design is also timeless design and in the best case also extends the useful life. Next comes the aspects of environmental sustainability, that is, to minimize the greatest emissions in the production of materials.

We live in times that require new approaches. Times in which we have to free ourselves from outdated views. As a value-driven company, we share common beliefs and want to lead the circular economy in our field.